Project Breakdown

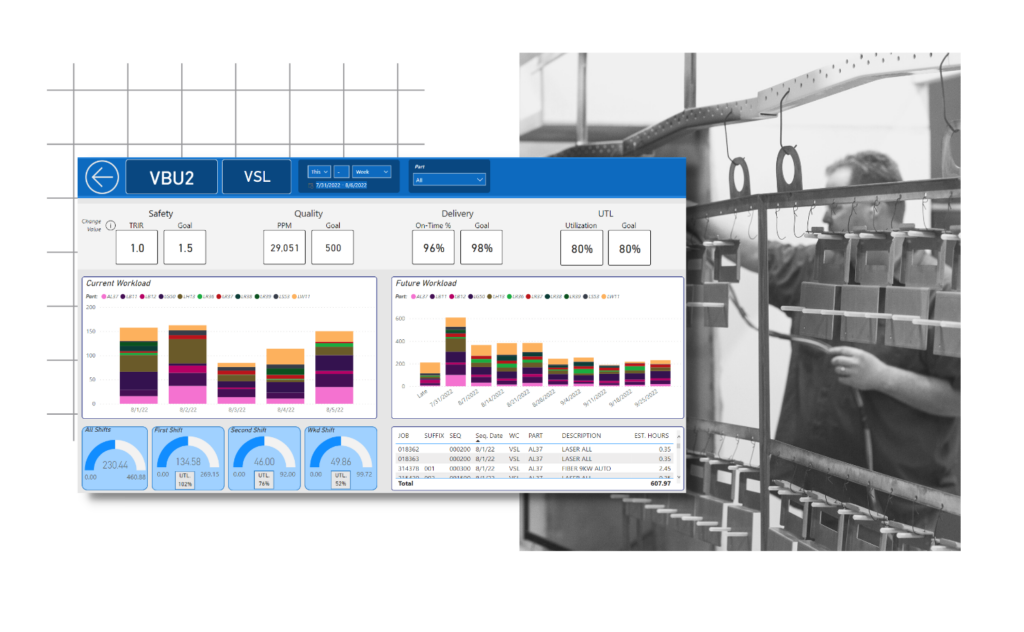

Custom Dashboard on Manufacturing Shop Floor Ups Productivity

The Challenge

DeWys recently went through an ERP change from Profit Key International to Global Shop. This major system change was a catalyst for digitizing one of their manual processes. At the time, DeWys relied on paper travelers– packets of instructions for each stage of manufacturing– that were being moved throughout the shop floor with the parts.

A collaborative Assessment process with the SPARK team led to DeWys replacing the paper travelers by pulling data from their ERP into an interactive labor performance dashboard that would display key metrics in real time on the shop floor.

Project Breakdown

- Small

- Custom Dashboard

Timeline

- 6 Months

- Assessment and Dedicated

- Development Team

Size of Team

- 1 PM

- 1 Developer

KPIs

Replaced paper travelers

with real-time dashboards

The Solution

With SPARK’s user-centered approach to technology design, DeWys was able to design the labor performance dashboard based on input from the shop floor operators.

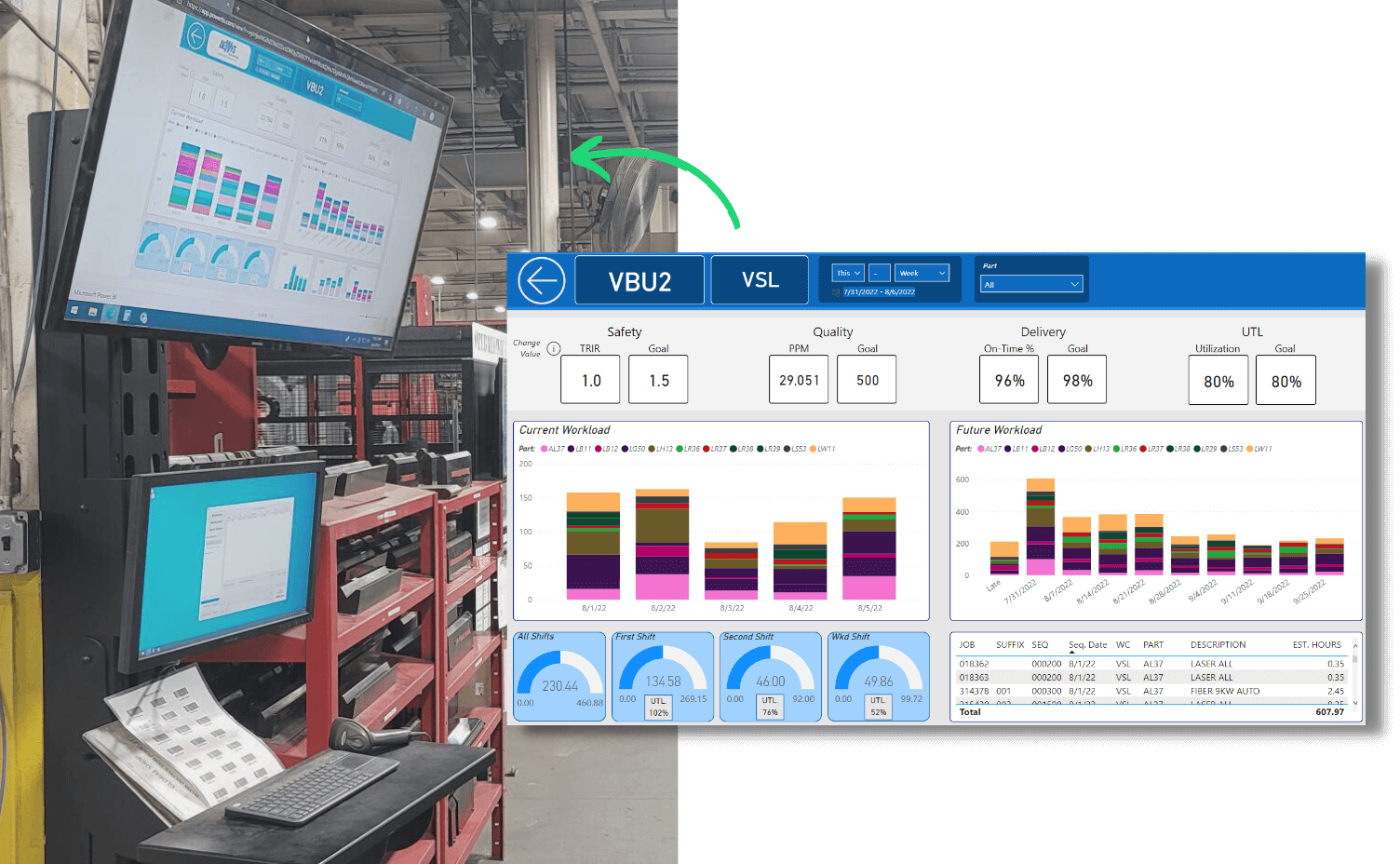

Displayed on 20 TVs around the shop, all 160+ workers can now see the status of different jobs and where they are in the manufacturing process. Operators are now proactive when planning work for the day, instead of waiting for the information.

As a dedicated software development partner, SPARK continues to work with DeWys to enhance the dashboard as well as future custom software projects.

Services provided

- Assessment

- Custom Software

- ERP Integration

- Dashboards

Technology used

- Microsoft Power BI

Client Review